Technical Information

Technical Information Power And Control Cables

Power And Control Cables Power Appendixes

Power Appendixes XLPE (Cross-liked Polyethylene)

XLPE (Cross-liked Polyethylene) Comparison Table of Cross Linking Methods

Comparison Table of Cross Linking Methods صفحه Comparison Table of Cross Linking Methods

|

|

Peroxide |

Silaine |

Irradiation |

|

Curing Media |

Organic Peroxide |

Silane Compound |

High Frequency Radiation |

|

Curing Equipment |

High Pressure & High Temperature Curing Duct |

Saturated Steam Bath |

Electron Beam Generator |

|

Strong Point |

Most Common No Thickness Limit |

Cheap Equipment Low Energy Cost High Speed Line |

High Speed Extrusion Low Running Cost |

|

Weak Point |

Expensive Equipment Limited Line speed High Energy Cost |

Wall Thickness Limit |

Expensive Equipment Limited Beam Cap. Wall Thickness Limit |

|

Application Voltage |

6000 v – 500 Kv |

150 V – 33 kv |

Max 600v |

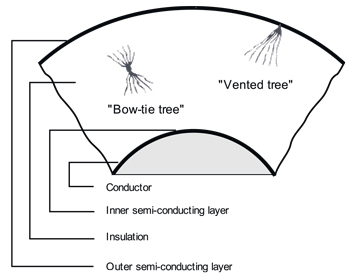

WATER TREEING CAUSES

Water treeing is the major defect of insulation of medium and high voltage cables.

It is independent of the Peroxide , Silaine or Irradiation methods of cross-linking and It can be categorized as following matters :

1- Impurities

related to the purity of the raw materials for the insulation and very important the semiconducting screens

2- Moisture in cable screens and insulation

2a. after production (is low both cables i.e. Silaine cured or dry cured ; was high in steam cured cables)

2b. during service operation (can be kept low in both cables i.e. Silaine cured or dry cured by water tight constructions)

3- Electrical Fields

Only Depends on fabrication of conductor (to be round) and tightness of layers and totally no sharp edges!

|

There are two most common

* Vented tree |

|